MOONEY VISCOSIMETER

Shearing-disc viscometer that measures the viscosity and the pre-vulcanisation characteristics of polymer and elastomeric blends (according to ISO 289 and ASTM D 1646 standards).

ABRASION TESTER

Abrasion tester with a rotating cylinder used to test the vulcanised rubber sample and plastic material resistance to wear and tear (according to the ISO 4649 and ASTM standards).

DMA

Dynamic-Mechanic Analyser which measures the mechanical proprieties of plastic materials depending on time, temperature and frequency according to different types of deformation. This instrument gives back information regarding very important material characteristics, for example the glass transition temperature, the vulcanisation process optimisation, the filler effect, the rigidity (elastic module), the damping and viscoelastic phenomena like creep and stress relaxation.

DSC

Differential Scanning Calorimeter which measures the temperatures and the heat flows associated with the thermic material transition like, for example, the glass transition, the crystallisation, the fusion, the vulcanisation kinetics reaction, the thermic and oxidising stability.

REBOUND TESTER

Schob like pendulum that determines the resilience of elastomeric materials with hardness between 30 and 85 IRHD points (according to ISO 4662 and ASTM D 7121 standards).

LABORATORY OVEN

Laboratory furnace equipped with thermoregulation P.I.D. that quickly ages elastomeric testers in air up until 250°C (according to ISO 188 and ASTM D 471 standards).

ELECTRONIC OZONE TESTER

Testing chamber used to determine the ozone resistance of normalised samples and elastomeric vulcanised or thermoplastic technical items (according to the ISO 1431-1 and ASTM D 1149 standards).

MOVING DIE (MD) RHEOMETER

Oscillating moving die rheometer which measures the cure characteristics of elastomeric compounds (according to ISO 6502 and ASTM D 5289 standards).

TENSOR TESTER WITH THERMIC CHAMBER

Electronic dynamometer working in traction and compression equipped with a temperature controlled chamber, to perform mechanical tests within a controlled temperature range between – 40°C ÷ + 250°C (like tensile, compression, shearing, bending and peeling tests according to ISO 34, ISO 37, ISO 813, ASTM D 412, ASTM D 624 and other standards).

MULTI-UNIT HARDNESS TESTER – SHOREA, SHORE D, IRHD-N, Micro IRHD

Multi-unit automatic hardness testing sistem to measure the elastomeric or plastic material hardness based on four different hardness scales: Shore A, shore D, Normal-IRHD and Micro-IRHD (according to ISO 868, ASTM D 2240, ISO 48, ASTM D 1415 standards).

ANALYTICAL BALANCE

Analytical balance to determine the density and the weight and volume percentage variation of compact compounds (not absorbent) through a hydrostatic method (according to ISO 1183-1 and ASTM D 297 standards).

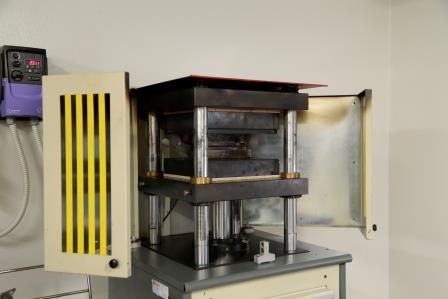

LABORATORY PRESS

Laboratory press to manufacture test specimens with reproducible features.

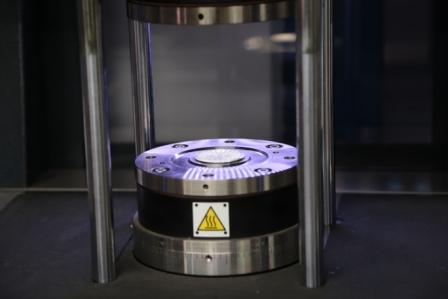

ARES RHEOMETER

High performance rheometer which applies rotational strains to the compounds – with various amplitudes, frequencies and temperatures – and measures the generated stress and the associated viscoelastic quantities.

INFRARED SPECTROMETER

Spectrometer that hits a polymeric sample with a wide frequency spectrum infrared light beam and measures its absorption, from which important chemical information can be obtained.

TGA

Thermogravimetric analyser (TGA) which measures the entity and the weight change of a material subjected to a heating ramp – or in isothermal mode – in a controlled atmosphere.

The instrument gives back quantitative information regarding important phenomena like the thermic decomposition, the dehydration and the oxidation.

TENSOR TESTER

Electronic dynamometer operating in traction and compression to measure the mechanic characteristics of elastomeric and plastic compounds in different modalities – traction, compression, shearing, peeling, and bending according to ISO 34, ISO 37, ISO 813, ASTM D 412, ASTM D 624 and other standards.